UV varnish, also known as UV varnish, is mainly composed of photosensitive resin, photoinitiator and other combination agents, which can be used on UV paint spraying machines. After the surface of the spraying material is irradiated by the UVLED curing machine, it changes from a liquid state to a solid state, so that the UV varnish on the surface of the spraying material is hardened.

Reasons why mercury lamps are not recommended

After the birth of UVLED curing machine, many printing manufacturers began to use UVLED curing machine to cure UV varnish, and mercury lamps gradually faded out of the market. Many UV varnish manufacturers also recommend that customers use UVLED curing machines instead of mercury lamps. why?

This is because UV varnish is a transparent liquid. When applied to a substrate surface, the thickness is very thin. The UV light source can easily penetrate the surface of the varnish to the bottom, so the optical density of the UV light source should not be too high. The higher the power, the more heat is generated, which can easily deform the surface of the print.

Due to the high temperature of the mercury lamp during the irradiation process, the light source contains thermal radiation. After the UV varnish coated on the surface of the paper absorbs the energy of the mercury lamp, the surface of the paper is penetrated by the UV varnish and the temperature rises, causing the paper to bend or curl, or even cause the paper to swell. In particular, some special plastic paper and paper with inconsistent coating on both sides, such as single-layer thin-coated paper, are easily deformed by heat.

Advantages of UVLED curing machine

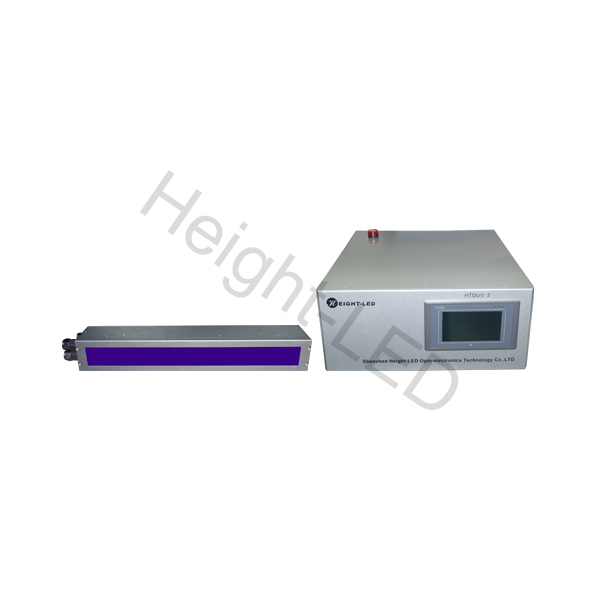

At present, UVLED curing equipment is mainly UVLED curing machine. UVLED curing machine as a cold light source curing machine, the emission light source is ultraviolet light, no radiation, simple operation, and can adapt to a variety of operating environments. Height-LED summarizes the main advantages of UVLED curing machines in UV varnish curing applications:

1.Second-speed curing, greatly shorten the curing and drying time, greatly shorten the drying time of UV varnish.

2. It can be used with the equipment: it can be connected to a roller or a self-jet screen printing machine, and the finished product is dried immediately after sizing to avoid transportation inconvenience.

3. The surface strength of the substrate coating is improved, and the appearance is bright.

4. Suitable for curing wood, wood, furniture, plastic board, decorative building materials, spectacle lenses, leather products and other materials.

5. High production efficiency and low energy consumption, the energy consumption is only 10%-20% of the traditional mercury lamp.

6. Cold light source, heat-sensitive material is available without damaging the material.

8. Small environmental pollution, UVLED curing machine does not contain heavy metals, no heat radiation.

9. The crosslinking density of the UV-cured varnish coating is much higher than that of thermal spray paint, so the coating has higher performance parameters in terms of strength, wear resistance, corrosion resistance, etc. Resistant to organic solutions such as gasoline for automobiles, especially the rounded paint layer and outstanding smoothness.

10. The UVLED curing machine has a long service life, easy maintenance, small footprint and simple operation.

As a manufacturer of UVLED curing equipment, Shenzhen Height-LED is committed to providing customers with a complete set of curing solutions. The products have standard products and can also customize products according to customer needs. If you have UVLED curing requirements, you can contact online customer service, or call for consultation and exchange.