When it comes to UV curing lamps, they are generally mercury vapor discharge lamps. Mercury vapor discharge lamps can be classified into high-pressure mercury vapor UV curing lamps and low-pressure mercury vapor UV curing lamps according to different purposes. Both types of UV curing lamps have a wavelength of 300-400 nm and a main peak wavelength of 365 nm. And the use is still a little different.

Low-pressure mercury vapor discharge UV curing lamps generally have low power, dozens of watts to several hundred watts. Generally, low-pressure mercury vapor UV curing lamps are used. The UV curing lamp has a good curing effect on the shadowless glue on the surface of crystal image, glass furniture, glass door and the like. And the effect of curing is also good, some soft binders can be cured with low-pressure mercury vapor lamps. But there are also deficiencies, can not be used with the open, and can not stand by, energy consumption, will produce ozone.

The high-pressure mercury vapor discharge UV curing lamp has a large power, and several hundred watts have been close to tens of thousands of watts. It is also because the UV glue requires a large amount of energy, so the high-pressure mercury vapor discharge lamp is used. The application of UV glue is relatively extensive, and the value of high-pressure mercury lamps is reflected in the best. Signs, circuit boards, printing plates, paper varnishes, and automotive motorcycle plastic parts are all used.

The application field of mercury vapor UV curing lamps is still not extensive enough, and its structure is one reason. It consists of four parts: a reflector, a UV trigger, a UV ballast and a tube. These applications have limited the application of mercury vapor UV curing lamps, and the high temperature and ozone are unavoidable, and the application cost is high, which promotes the new solution of new UV curing lamps.

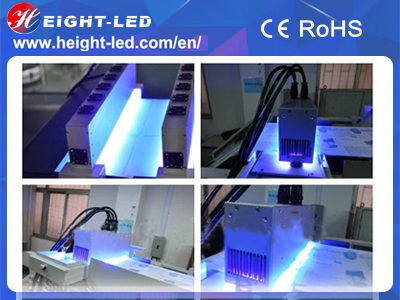

The new generation of UVLED curing lamps are energy efficient, environmentally friendly, safe and efficient. The radiation power conversion rate of UVLED lamps is about 35%, which can save 80% compared with halogen lamps, and can save electricity costs 30,000-50,000 yuan a year. In the case of high temperature, the halogen lamp will destroy the oxygen structure and cause chemical reaction, which will produce ozone. The long-term inhalation of ozone by the human body is easy to obtain lymphoma. Compared with halogen UVLED curing lamps, it is more environmentally friendly and will not cause damage to the human body. The LED startup voltage is only 3.3V, which is a safe voltage. The UVLED curing lamp is ready to use and can be shut down during production intervals, greatly improving production efficiency.