At present, most printing manufacturers use more environmentally friendly UV inks, and UV ink curing equipment is mainly divided into mercury lamps and UVLED curing machines. UV curing equipment has also undergone a continuous development and improvement process, and the production process with mercury lamp irradiation as the mainstream has been adopted for a long time. However, due to the high cost of equipment, high maintenance costs, rapid UV light intensity attenuation, increased surface temperature of the irradiated components, large volume, expensive consumables, mercury pollution and other defects, the industry has been committed to improving, but due to the limitations of the original hardware It is difficult to break through.

The advent of UVLED curing light source has brought revolutionary changes to the UV curing industry. It has the characteristics of constant light intensity, temperature control, small size and environmental protection, and relatively low procurement costs and almost zero maintenance costs. It has played a role in promoting the quality improvement and energy saving of the UV curing process.

What are the advantages of UVLED over traditional UV curing equipment?

1. Long service life

Compared with traditional UV curing equipment, the service life of traditional UV lamps is 1000 hours, among which the service life of mercury lamps is 800-3000 hours, and the service life of UVLED curing machine can reach 20,000-30000 hours. UVLED curing equipment can be turned on instantaneously only when the ultraviolet light source is needed, while the traditional mercury lamp curing equipment has slow start-up and opening and closing affects the life of the lamp. It needs to be lit all the time during work, which causes unnecessary power waste and shortens it. The life of the mercury lamp.

2. No heat radiation

UVLED converts 15%~30% of the input electric energy into usable UV light, without UVC wavelength and infrared wavelength harmful to the human body, energy saving, low consumption, and no heat radiation. It is suitable for thermally sensitive and high-precision bonding process requirements such as plastic substrates, lens bonding, electronic products, optical fibers and cables.

3. Environmental protection and pollution-free

The traditional mercury lamp curing machine adopts the mercury lamp lighting method. There is mercury in the lamp. The waste disposal and transportation are very troublesome. The short wave emitted will cause the oxygen in the air to react to produce ozone, which is harmful to the human body. System, improper handling will cause serious pollution to the environment. The UV LED curing machine uses semiconductors to emit light, and there is no pollution to the environment, so it is more environmentally friendly to use the LED curing machine.

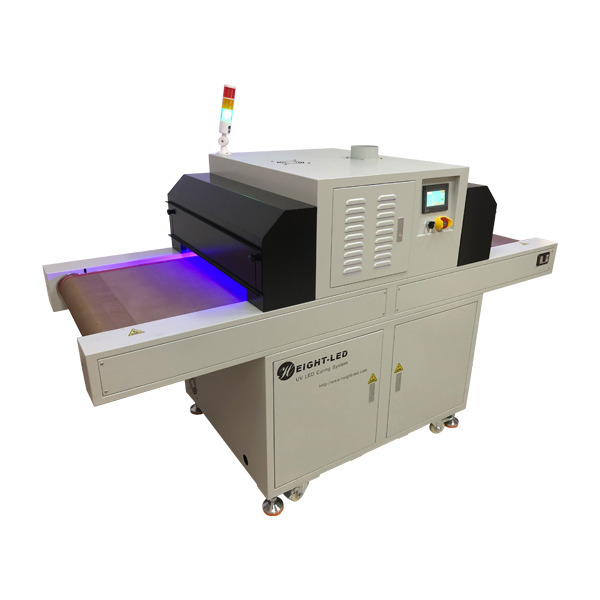

Shenzhen Height-LED specializes in the production of uvled curing equipment, and can customize suitable uvled curing systems for customers. Welcome to consult.