Curing is a process of strengthening a product. The existence of UVLED curing system is a curing operation method that will take a long time to dry naturally and the adhesion effect is not very ideal. Therefore, in many industrial production processes, UVLED curing equipment is selected to speed up the curing process of the product.

The application of UVLED curing system in the microelectronics industry is also very extensive. For example, for the daily use of mobile phones, the camera lens, as well as the receiver, microphone and other spare parts are all entered into the curing system after the installation is completed to complete the whole process. The curing of the product has a better adhesion effect, and the parts of the mobile phone are closer together.

In addition, the adhesion of the bearings, coils and chips in the hard disk needs to be cured in the later stage, because only after curing can it play a better adhesion and let the glue play a greater role. This in itself is a feature of glue.

In addition, in the production of digital cameras and semiconductor chips or sensors, after the products are cured by the UVLED curing system, the accessories can be firmly fixed in the existing position and can be maintained for a very long time. Even if it is attacked by external force during use, it will not have any impact on the stability of the internal parts of the product.

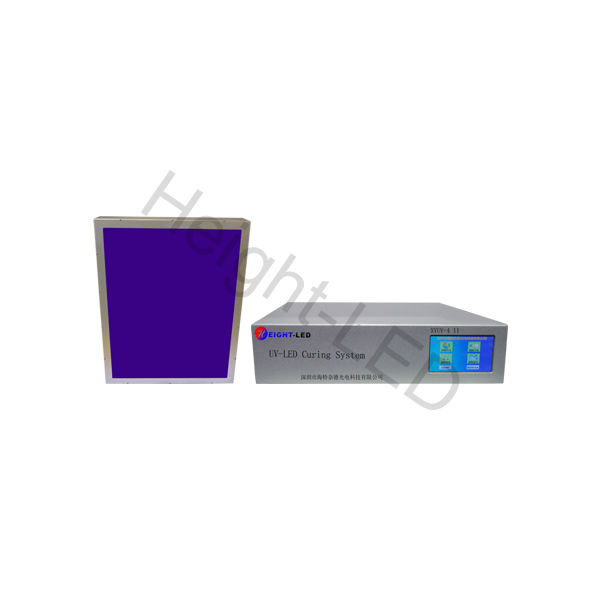

As a manufacturer of UVLED curing equipment, Shenzhen Height-LED is committed to providing customers with a complete set of curing solutions. The products have standard products and can also customize products according to customer needs. If you have UVLED curing requirements, you can contact online customer service, or call for consultation and exchange.