The ultraviolet output of 365nm wavelength in UVLED curing machine is pure ultraviolet light, and its monochromatic light does not contain infrared, which avoids the influence of inappropriate light waveband radiation on the firmware. So which industries are usually used for curing opportunities in this band?

1. UV glue in optical lenses

Because the light band of this UVLED curing machine does not contain infrared and heat radiation in the 365nm band, it can effectively reduce the temperature of the surface of the object, which can reduce the energy consumption during the production process of the product and increase the service life of the product. It is very suitable for process applications that require lower temperature, high precision, and low adhesion. For example, the wavelength of UV glue in optical lenses is 365nm.

2. Touch display

Nowadays, people’s lives are becoming more and more intelligent. Many smart phone screens, computer displays and flat panel displays are operated by touch, which is simple and convenient and saves time. Especially in the Asia-Pacific region, it has become the largest and growing in the touch screen manufacturing industry. The fastest regional market. The 365nm band UVLED curing machine is popular with manufacturers in emerging industries because of its continuous and stable heat output, so it is also widely used in the manufacturing process of touch screens.

3. Smart phone

The UVLED curing machine in the 365nm band is very suitable for the manufacture of smart phones, especially in the production of camera modules, camera lenses, earphones, microphones and casings. You can see its shadow, because it can adjust the temperature of radiation, and There is also a good exhaust system, which can discharge unnecessary heat produced during the production process, making this band of curing machines very widely used in smart phones.

4. Disk Drive

The rapid curing function of the 365nm UVLED curing machine is particularly suitable for the protection of disk drive components. UVLED curing technology provides higher reliability, higher productivity and higher output for such applications, and because this curing machine itself has a longer life than traditional curing machines, it can be used for a longer time. The cycle of product replacement is reduced, and the production cost of precision instruments can be saved, so it is deeply favored by operators.

5. Small speaker

The assembly of such small speakers involves the use of curing adhesives at multiple points and connecting parts that may be deformed or damaged by overheating. UVLED curing machine can provide low temperature and UV output to meet the challenges of output growth.

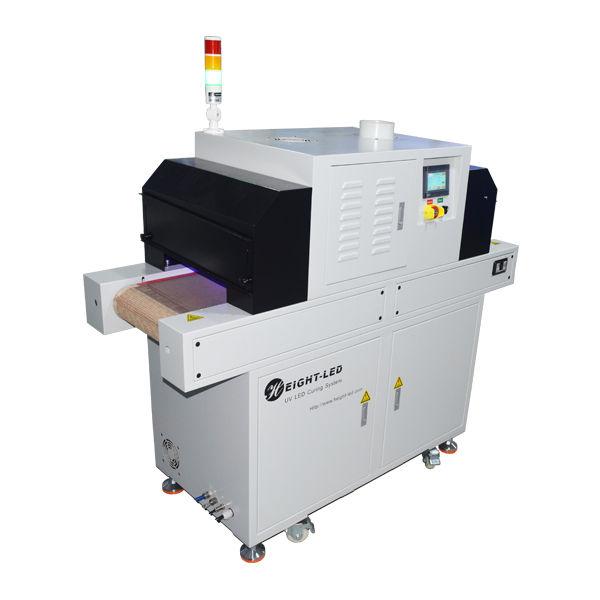

As a professional manufacturer of UV curing equipment, Shenzhen Height-LED has rich curing experience and can customize a suitable UV curing machine according to the customer's process. Friends in need are welcome to consult.